Plybond Tester

Price 165000.0 INR/ Unit

Plybond Tester Specification

- Voltage

- 220 Watt (w)

- Temperature

- As per industry norms Celsius (oC)

- Operate Method

- DIGITAL

- Power Supply

- 220

- Frequency

- 50 Hertz (HZ)

- Automation Grade

- A1

- Material

- SS & MS

- Product Type

- Steel

- Application

- Industrial

- Weight

- 40 KG Kilograms (kg)

- Power

- 220 Watt (w)

- Color

- Green paint Coated

- Test Stroke

- 15

- Control Mode

- DIGITAL

Plybond Tester Trade Information

- Minimum Order Quantity

- 1 Unit

- Supply Ability

- 100 Units Per Month

- Delivery Time

- 7 Days

- Main Domestic Market

- All India

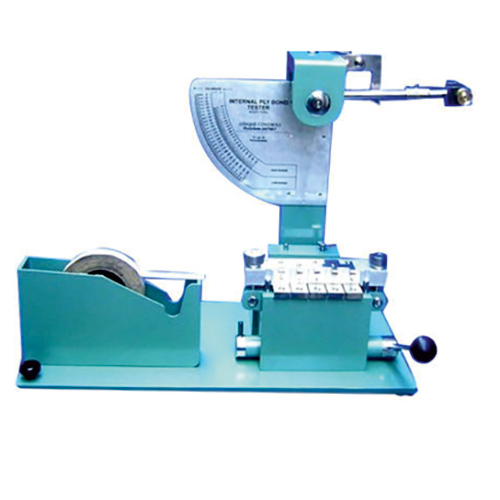

About Plybond Tester

A Digital Plybond Tester is a precision instrument used to measure the internal bond strength of paper and paperboard especially multi-ply materials like duplex board, kraft board, or corrugated paper. It helps determine how well the layers of paper are bonded together.

---

Key Features of a Digital Plybond Tester:

Digital Display: Shows readings in joules or ft-lb with high accuracy.

Microprocessor-based Control: Ensures repeatability and reliability of results.

User-Friendly Interface: Simple button operation and LED/LCD screen.

Auto Reset Function: For ease of repeated testing.

Sample Clamping System: Holds test specimen securely during test.

Adjustable Release Mechanism: Controls pendulum release for consistent energy transfer.

---

Typical Test Process:

1. A paperboard specimen is clamped between two plates.

2. A pendulum or hammer mechanism strikes the bonded plies.

3. The tester measures the energy absorbed in separating the plies.

4. The result reflects internal bond strength, crucial for packaging applications.

---

Technical Specifications (may vary by model):

ParameterValue

Test Range00.5 ft-lb (or 00.7 J)

Accuracy1% of reading

DisplayDigital LCD or LED

Power Supply220V / 50Hz or battery-operated

CalibrationAuto or manual calibration

---

Applications:

Duplex board quality testing

Corrugated board ply strength checking

Carton manufacturing

DIGITAL PLY BOND TESTER

Model: FSC-DPB-1003 (as seen on the label)

---

Manufacturer (visible on the side machine)

FIBER SCIENTIFIC COMPANY, India known for paper testing equipment.

---

Key Components in the Image

1. Digital Control Panel (Top left):

Keypad for setting up test parameters.

Digital screen for test results (usually in Joules or ft-lb).

2. Sample Clamping Station (Middle):

Equipped with multi-position clamps to hold paper specimens.

Tight and aligned to ensure accurate testing.

3. Pendulum/Impact Mechanism (Right upper vertical rod):

Applies impact to separate the bonded layers.

Operated either manually or through digital trigger.

4. Roll of Tape (left side):

Used for preparing or positioning the paper samples.

5. Manual Lever/Handle (Bottom right):

Used for loading/unloading or resetting the pendulum.

---

How It Works

1. Cut and place a sample between clamps.

2. Secure it using the rotating knobs.

3. Initiate test via control panel or lever.

4. The pendulum hits the bonded area.

5. The energy absorbed during delamination is recorded digitally.

---

Typical Output

Bond strength is shown in ft-lb, Nm, or Joules.

Higher values indicate stronger ply bonding in the paper.

FAQs of Plybond Tester:

Q: What is the power requirement for the Plybond Tester?

A: The Plybond Tester requires a power supply of 220 Watts and operates at 220 volts with a frequency of 50 Hertz (Hz).Q: What is the weight of the Plybond Tester?

A: The Plybond Tester weighs 40 kilograms (kg).Q: What material is used for the construction of the Plybond Tester?

A: The Plybond Tester is constructed using Stainless Steel (SS) and Mild Steel (MS).Q: What is the stroke length for testing with the Plybond Tester?

A: The Plybond Tester offers a test stroke of 15.Q: What type of control mode does the Plybond Tester feature?

A: The Plybond Tester has a digital control mode and operates digitally.Q: What color coating is used on the Plybond Tester?

A: The Plybond Tester is coated with green paint.Q: What is the automation grade of the Plybond Tester?

A: The Plybond Tester has an automation grade of A1.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Laboratory Testing Equipment Category

ANALOG BURSTING STRENGTH TESTER SINGLE HEAD

Price 45000 INR / Unit

Minimum Order Quantity : 1 Unit

Material : Stainless steel and M.S

Power Supply : 230V ;AC

Control Mode : ANALOG

BOX COMPRESSION TESTER (1000*1000)

Price 285000 INR / Unit

Minimum Order Quantity : 1 Unit

Material : SS & MS

Power Supply : 220 V

Control Mode : DIGITAL

Bursting strength tester

Price 75000 INR / Billions Of Unit

Minimum Order Quantity : 1 Bottle

Usage : Industrial

Laminar Air Flow

Price 2500 INR / Unit

Minimum Order Quantity : 1 Unit

Usage : Industrial

Power Supply : Electric

Control Mode : Manual

Send Inquiry

Send Inquiry